Thermal processing

Bodycote provides thermal processing services which improve material properties such as strength, durability and corrosion resistance, enabling manufacturers' components to work more efficiently with significantly extended operational lifetimes. Bodycote's services consist of a number of core technologies: heat treatment and metal joining, hot isostatic pressing (HIP) and surface technology.

Heat treatment and metal joining

Heat treatments are controlled processes used to alter the microstructure of materials, such as metals and alloys, to impart properties which benefit the working life of a component, for example, increased surface hardness, temperature resistance, ductility and strength. Metal joining includes specialised processes such as electron beam welding, vacuum and honeycomb brazing – complex operations requiring a fusion of expertise and technology.

Bodycote offers an extensive range of heat treatment services and metal joining techniques – including three of the Group's Specialist Technologies: Specialty Stainless Steel Processes (S3P), Corr-I-Dur® and Low Pressure Carburising – from facilities around the world. With unmatched capacity and computerised systems, Bodycote facilities can process a wide range of component sizes to exacting standards with reliable, repeatable results.

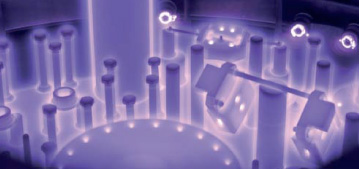

Hot isostatic pressing (HIP)

HIP Services and HIP Product Fabrication (HIP PF) – two of Bodycote's Specialist Technologies – combine very high temperature (up to 2,000 °C) with inert gas under very high pressure (up to 30,000 psi – equivalent to that found at an ocean depth of 11,000m such as at the bottom of the Mariana Trench in the Pacific Ocean). HIP can be used to eliminate porosity in castings and, by using HIP PF, enables the consolidation of encapsulated powders into dense materials and the bonding of dissimilar materials to manufacture unique cost-effective components. Every week a typical Bodycote HIP plant will process many tons of titanium, aluminium, steel and super-alloy castings, removing porosity and improving the performance of parts such as turbine blades and oilfield components.

With the largest operational capacity in the world and a wide variety of equipment sizes, Bodycote HIP is able to accommodate large volumes of small product as economically as large individual components.

Surface technology

The Group's Specialist Surface Technologies are used extensively to prolong the working life of components and protect them from environmental factors such as corrosion and abrasion. The range of surface technologies available from Bodycote covers a wide variety of applications, providing manufacturers with solutions to meet requirements such as durability, wear resistance, improved hardness and electrical conductivity.

Bodycote is a provider of specialised plasma spray, high velocity oxy fuel (HVOF) and thermochemically formed coatings treatments and is able to surface engineer components (including complex geometric shapes and internal bores) that are designed to operate in the most demanding of industrial applications.

The supplier of choice

Bodycote has become the supplier of choice for the world's most respected and innovative engineering companies by providing highly efficient, cost-effective services to the highest quality standards through strategic investment in people and the latest technology, equipment and quality systems.

By outsourcing non-core but vitally important thermal processing requirements to Bodycote, customers are able to concentrate their business resources where they are needed most. Bodycote's services offer tangible benefits to customers such as reduced equipment maintenance, capital expenditure, energy costs, people costs and a major reduction in CO2 emissions.

Bodycote has a long history of successful outsourcing relationships, working with a range of customers from global to local manufacturers. In many cases, these relationships lead to component and service-specific arrangements, which provide protection for the customer from supply disruption by leveraging Bodycote's unique facility network, and optimising asset utilisation. Such arrangements are normally exclusive in character and provide the basis for mutual business development, with both companies freed to concentrate capital and other resources on core competencies.

Making innovations possible

Bodycote's extensive facilities and expertise mean the identification and provision of technical solutions can expand far beyond customers' in-house capabilities, helping to realise goals more quickly and more cost-effectively.

Bodycote's experienced staff are able to innovatively apply existing or enhanced technologies to optimise customers' specifications, tailoring and combining processes to deliver value-adding services. This may include the enhancement of specific processes and equipment for a customer or verification of materials or designs, prior to their application.